DETAILED

INFORMATION

详细信息

- > Rubber foam insulation materials

- > High end wall rock wool board

- > Polyurethane composite plate

- > Plastic extruded board

Class1 rubber foam for engineering

Rubber foam insulating tube for split type air conditioner

Composite veneer rubber foam products

FM Antifungal and antiseptic type Rubber foam

Rock wool curtain wall and composite wall system

Rock wool sandwich panel system

Blessed thermal insulation industrial cluster

Address:

dacheng county,langfang city, hebei province,Quancun industrial zone

Order Telephone:

400-036-8588

Email: hbplsd@163.com

Website: www.zgplsd.com

您的当前位置:首页 > Product >Plastic extruded board

Plastic extruded board

2020-10-20 Classification:Product > Plastic extruded board

Extruded polystyrene foam board, referred to as Extrusion board, also known as XPS board. Class B1 Extrusion board is made of polystyrene resin and polymer, which is heated and mixed together, and is injected with catalyst and flame retardant. After extrusion, the continuous closed-cell foamed rigid foam plastic sheet is extruded. The inner part of the sheet is an independent closed-cell structure. It is a kind of environmental protection protection with excellent properties, such as flame-retardant, high compression resistance, low water absorption, moisture-proof, air-proof, light weight, corrosion resistance, ultra-anti-aging (almost no aging for long-term use), low thermal conductivity and so on. Warm materials.

Class B1 extruded board is widely used in dry wall insulation, plane concrete roof and steel structure roof insulation, low-temperature storage ground, parking platform, Airport runway, highway and other fields of moisture insulation, control of ground frost heave, is the construction industry cheap, high-quality insulation, moisture-proof materials.

main application

1, widely used for wall insulation, flat concrete roof and steel roof insulation.

2. For low temperature storage ground, parking platform, Airport runway, highway and other fields of moisture insulation.

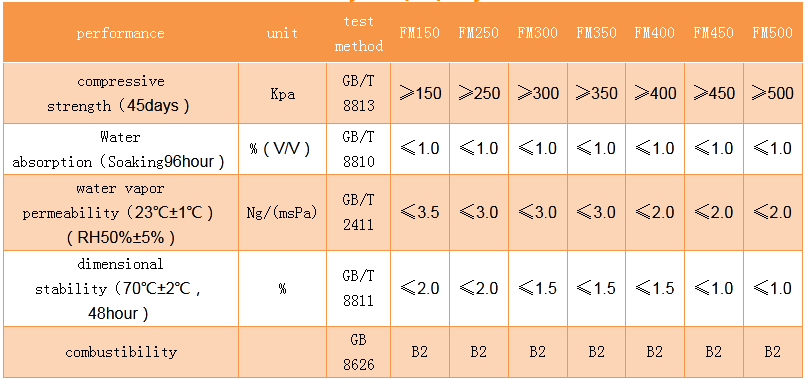

Performance characteristics

Excellent thermal insulation

Bleseed B1 grade extrusion board has the characteristics of high thermal resistance, low linearity and low expansion ratio. The closed-cell rate of its structure reaches more than 99%, forming a vacuum layer, avoiding air flow and heat dissipation, ensuring its insulation performance is durable and stable. Compared with the 80% closed-cell rate of foamed polyurethane, the leading advantage is self-evident. Practice has proved that 20 mm thick XPS Extrusion insulation effect is equivalent to 50 mm thick foamed polystyrene, 120 mm thick cement perlite. Therefore, this material is the best choice for building insulation at present.

Excellent high compressive strength

Because of the special structure of the extruded board, its compressive strength is very high and impact resistance is very strong. According to the different types and thickness of the extruded board, its compressive strength reaches 150-500 Kpa and can bear the ground load of various systems. It is widely used in geothermal engineering, expressway, Airport runway, square ground, large-scale cold storage and car interior decoration and protection. Wen and other fields.

High quality water repellency and moisture resistance

Water absorption is an important parameter for measuring thermal insulation materials. After absorbing water, the insulation performance of the insulation material decreases. At low temperature, the water sucked in is easy to freeze, destroying the structure of the insulation material, thus reducing the compressive and thermal insulation performance of the board. Because the polystyrene molecular structure itself does not absorb water, the plate molecular structure is stable, no gap, to solve other materials leakage, penetration, frosting, condensation and other problems.

Light weight and easy to use

The complete closed-cell foaming chemical structure and honeycomb-like physical structure of Blessed B1 grade extrusion board make it light weight and high strength, easy to cut, transport, and easy to break and install.

Good stability and corrosion resistance.

The chemical properties of the extruded heat preservation board are extremely stable, and it will not degrade due to water absorption and corrosion. It can still maintain its superior performance in high temperature environment. According to the relevant information, the extruded heat preservation board can remain excellent even after 30-40 years of use. Different properties, and will not decompose or mildew, there is no volatilization of toxic substances.

Product environmental performance

Blessed B1 grade extrusion board has been tested by the relevant departments of the state with stable chemical performance, no volatile harmful substances, harmless to human body, and high fire-proof grade, non-flammable and so on. The raw materials for production are environmentally-friendly materials without any industrial pollution. The product is environmentally-friendly building materials.

.jpg)

Physical property

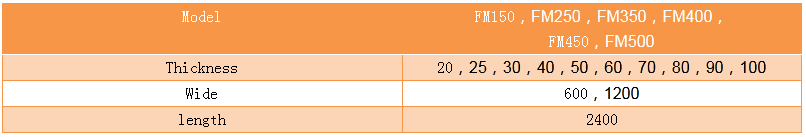

Standard Specification(mm)

Thermal conductivity (90 days after production)